China National Intellectual Property Administration

utility model patent

(10) Authorization Announcement Number: CN 210365265 U

(45) Authorization Announcement Date: April 21, 2020

(21) Application number: 201920494758.3

(22) Application date: April 12, 2019

(73) Patent holder: Jiangsu Taihua Plastic Products Co., Ltd

Address: No. 155 Taigao Road, Sixiang Town, Hailing District, Taizhou City, Jiangsu Province, China. Jiangsu Taihua Plastic Products Co., Ltd

(72) Inventor: Zhang Shufeng

(51)lnt. C1.

B65D 90/00(2006 .01)

B65D 88/16(2006 .01)

(54) Utility model name: A new type of leak proof plastic FIBC bags

(57) Abstract

The utility model discloses a new type of leak proof plastic container bag, comprising a plastic bag body, an inner bag, a feeding port, a leak proof belt, a nylon belt, a sling, a circular sewing fixing belt, a discharging port, an elastic belt, and a tightening belt. By setting the length of the nylon belt to be consistent with the height of the plastic bag body, the nylon belt not only makes the connection between the plastic bag body and the inner bag more stable, but also prevents leakage from the side walls of the plastic bag body and the inner bag; By fastening the elastic band with a tight strap, the feeding port can be locked to prevent material leakage at the feeding port, which has the advantages of easy sealing and high efficiency. The top of the feeding port is equipped with a circular sewing fixing belt, and the bottom outer wall of the circular sewing fixing belt is sewn and connected to the bottom inner wall of the inner bag. Through the setting of the circular sewing fixing belt, the feeding port can be directly sealed and connected to the inner bag, thereby preventing items from leaking from the sewing position of the feeding port.

claims

1. A new type of leak proof plastic container bag, comprising a plastic bag body (1), characterized in that: the inner wall of the plastic bag body (1) is sewn with an inner bag (2), and the top of the plastic bag body (1) is sewn with a feeding port (3), and a leak proof tape (4) is installed above the feeding port (3). A nylon tape (5) is provided at the corner of the outer wall side wall of the plastic bag body (1), and a sling (6) is sewn on the top of the nylon tape (5). A discharge port (8) is provided at the center of the bottom of the plastic bag body (1).

2. A new type of leak proof plastic container bag according to claim 1, characterized in that the outer wall of the discharge port (8) is sewn with an elastic band (9), and the elastic band (9) is wrapped with a tight strap (10) inside.

3. A new type of leak proof plastic container bag according to claim 1, characterized in that the nylon strap (5) is sewn and connected to the inner wall of the inner bag (2).

4. A new type of leak proof plastic container bag according to any one of claims 1 or 2, characterized in that: the top of the discharge port (8) is provided with an annular sewing fixing belt (7), and the bottom outer wall of the annular sewing fixing belt (7) is sewn and connected to the inner bottom inner wall of the inner bag (2).

5. A new type of leak proof plastic container bag according to claim 1, characterized in that the feeding port (3) and the discharging port (8) are arranged on the same axis on the plastic bag body (1).

Instruction manual: A new type of leak proof plastic container bag

TECHNICAL FIELD

[0001] This utility model relates to the field of container bag technology, specifically a new type of leak proof plastic container bag.

Background technology

[0002] A container bag is a flexible transportation packaging container widely used for the transportation and packaging of powdered, granular, and block shaped items such as food, grains, medicine, chemicals, and mineral products. Developed countries commonly use container bags as packaging products for transportation and storage, which have the characteristics of low price, firm and reliable, moisture-proof and sun protection.

[0003] Existing container bags use existing plastic inner bags for loading. Considering cost issues, the upper part is generally not sewn, and the most prone to leakage is powder, which leaks from the bottom or a small portion of the side. The upper part is not subjected to force and is less likely to leak, and the discharge port at the bottom is the most prone to leakage. The existing bottom discharge port structure is relatively simple and not easy to seal.

Utility Model Content

[0004] The technical problem solved by the present utility model is to overcome the defects of easy leakage and inconvenient sealing in the prior art, and provide a new type of leak proof plastic container bag. The new type of leak proof plastic container bag has the characteristics of leak prevention and easy sealing.

[0005] In order to achieve the above objectives, the present utility model provides the following technical solution: a new type of leak proof plastic container bag, comprising a plastic bag body, an inner bag sewn on the inner wall of the plastic bag body, and a feeding port sewn on the top of the plastic bag body. An anti leakage belt is installed above the feeding port, and a nylon belt is set at the corner of the outer wall side wall of the plastic bag body. A sling is sewn on the top of the nylon belt, and a discharge port is set at the center of the bottom of the plastic bag body.

[0006] Preferably, the outer wall of the discharge port is sewn with an elastic band, and a tight strap is wrapped inside the elastic band.

[0007] Preferably, the nylon strap is sewn and connected to the inner wall of the inner bag.

[0008] Preferably, the top of the discharge port is equipped with a circular sewing fixing belt, and the outer wall of the bottom of the circular sewing fixing belt is sewn and connected to the inner wall of the inner cavity of the inner bag.

[0009] Preferably, the feeding and discharging ports are set on the same axis on the plastic bag body.

[0010] Compared with the prior art, the beneficial effect of the present utility model is that by setting the length of the nylon belt to be consistent with the height of the plastic bag body, the nylon belt not only makes the connection between the plastic bag body and the inner bag more stable, but also prevents leakage from the side walls of the plastic bag body and the inner bag; By fastening the elastic band with a tight strap, the feeding port can be locked to prevent material leakage at the feeding port, which has the advantages of easy sealing and high efficiency. The top of the feeding port is equipped with a circular sewing fixing belt, and the bottom outer wall of the circular sewing fixing belt is sewn and connected to the bottom inner wall of the inner bag. Through the setting of the circular sewing fixing belt, the feeding port can be directly sealed and connected to the inner bag, thereby preventing powder, particles, and block shaped items from leaking from the sewing port of the feeding port and making the structure of the feeding port more stable.

Attached image description

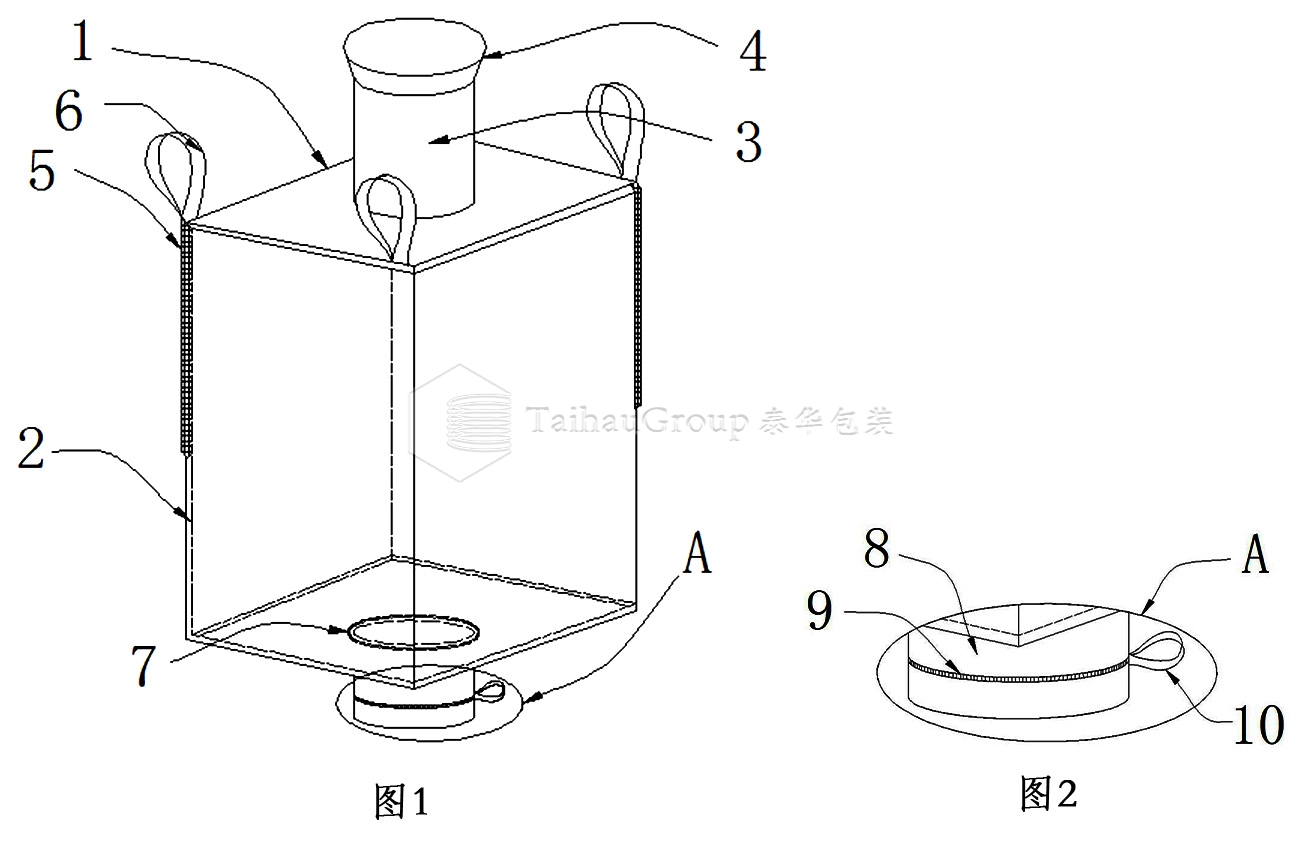

[0011] Figure 1 is a schematic diagram of the structure of the present utility model;

[0012] Figure 2 is an enlarged view of point A in Figure 1 of the present utility model.

[0013] In the figure, label: 1. Plastic bag body; 2. Inner bag; 3. Feed inlet; 4. Leak proof tape; 5. Nylon strap; 6. Sling; 7. Circular sewing fixing belt; 8. Discharge port; 9. Elastic band; 10. Tighten the straps.

Embodiment

[0014] The following will provide a clear and complete description of the technical solution in the embodiments of the present utility model, based on the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present utility model, not all of them. Based on the embodiments in this utility model, all other embodiments obtained by ordinary skilled persons in this field without creative labor are within the scope of protection of this utility model.

[0015] Please refer to Figure 1-2. The present utility model provides a technical solution: a new type of leak proof plastic container bag, comprising a plastic bag body 1, an inner bag 2 sewn on the inner wall of the plastic bag body 1, and a feeding port 3 sewn on the top of the plastic bag body 1. An anti leakage belt 4 is installed above the feeding port 3. A nylon belt 5 is set at the corner of the outer wall side wall of the plastic bag body 1, and the nylon belt 5 is sewn and connected to the inner wall of the inner bag 2. The nylon belt 5 not only makes the connection between the plastic bag body 1 and the inner bag 2 more stable, but also prevents leakage of the side walls of the plastic bag body 1 and the inner bag 2. The top end of the nylon belt 5 is sewn with a sling 6, which is a sling 6. Located at the top four corners of the plastic bag body 1, the bottom center of the plastic bag body 1 is equipped with a discharge port 8. The feeding port 3 and the discharge port 8 are arranged on the same axis on the plastic bag body 1, The outer wall of the discharge port 8 is sewn with an elastic band 9, and a tight strap 10 is wrapped inside the elastic band 9. By binding the elastic band 9 with the tight strap 10, the discharge port 8 can be locked to prevent material leakage at the discharge port 8, which has the advantages of high work and efficiency. The top of the discharge port 8 is equipped with a circular sewing fixing belt 7, and the bottom outer wall of the circular sewing fixing belt 7 is sewn and connected to the inner wall of the inner bag 2. Through the setting of the circular sewing fixing belt 7, the discharge port 8 can be directly sealed and connected to the inner bag 2, thereby preventing powder, particles, and block shaped items from leaking from the sewing of the discharge port 8 and making the structure of the discharge port 8 more stable. The sentence is:.

[0016] Working principle: Firstly, the elastic band 9 is restrained by the tightening strap 10 to lock the feeding port 8. Then, powdered, granular, and block shaped items such as food, grains, medicine, chemicals, minerals, etc. are placed into the plastic bag body 1 from the feeding port 3. After the plastic bag body 1 is filled and the direction is stable or straight, it is convenient for external forklifts or other handling devices to lift and hook the sling 6. During the handling process, the length of the nylon strap 5 is set to be consistent with the height of the plastic bag body 1. The nylon strap 5 not only makes the connection between the plastic bag body 1 and the inner bag 2 more stable, but also facilitates the lifting and hooking of the sling 6 by external forklifts or other handling devices. It can also prevent leakage from the side walls of plastic bag body 1 and inner bag 2. When cutting, the elastic band 9 is loosened by tightening the strap 10, The material can be discharged from the discharge port 8.

[0017] Although the embodiments of the present utility model have been shown and described, it will be understood by those skilled in the art that various changes, modifications, substitutions, and variations can be made to these embodiments without departing from the principles and spirit of the present utility model. The scope of the present utility model is limited by the appended claims and their equivalents.